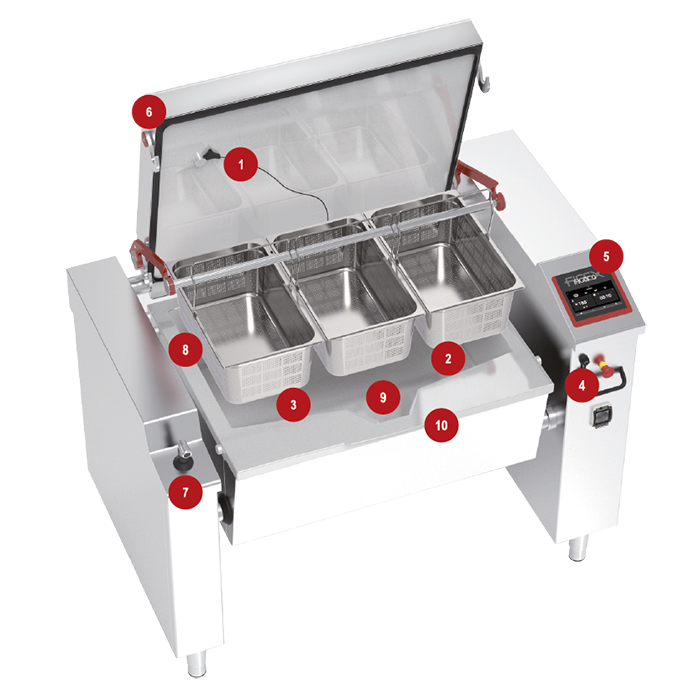

Figaro by Firex is the innovative industrial braising pan, compact in size and extremely fast in heating.

Figaro serves as braising pan, kettle, fryer and traditional stove: one single machine that offers the possibility of cooking also under pressure.

Figaro: versatile in cooking, quick in heating, compact in size

A new heating technology makes Figaro 4 times faster than a traditional braising pan.

Capacity: 100 | 150 litres

Versions with pressure cooking and drain available.

Precise and constant monitoring of the temperature of the product in the tank.

Download HACCP data and upload/download recipes

Easy and intuitive touch screen

For the pressure lid and basket lifting system

Managed by the electronic board

For hot and cold water load

Anti-overflow control when emptying the tank

Contact the chef

Schedule a demonstration appointment to see our machines in action. To find out which Firex solution best suits your needs, complete the form on the side and book your demonstration. During a tailored demo, our chef will prepare your recipe directly in the Firex demonstration kitchen.

You will have the opportunity to observe and personally experience all the Firex technology and discover how it can facilitate your daily work.

Figaro Touch Control (FTC): easy and intuitive touch screen

The Figaro Touch Control is the next-generation electronic board, extremely user-friendly and suitable to any operator. It features an intuitive interface to create and store complete and customised cooking programs. It manages the energy use in autonomy in order to ensure precise, quick and even reaching of the temperature in the tank.

A technology that guides you step by step through the recipe and demands the operator’s intervention only when necessary.

FTC is connected to the “Open kitchen” cloud platform. You’ll be able to monitor: data, consumptions, processes, cooking modes, software updates and any maintenance needs.

My cuisine is a fusion of various gastronomic traditions of different continents

My cuisine is a fusion of various gastronomic traditions of different continents and my goal is to offer guests a unique taste experience. Lots of different dishes require plenty of resources which is why I was looking for an ally that is able to manage the high variety of preparations safely and in autonomy.

Since when we introduced Figaro in our kitchen, I can program entire processes and leave it to the machine to complete them.

Figaro can be used to braise, boil, fry, steam cook or cook under pressure and guarantees to achieve always consistent results and to have outstanding quality. Figaro works smartly and provides perfect temperature control and this makes me confident I always serve my guests delicious recipes.

Chef Enrico Pivieri

Restaurant”Il Cavallo Scosso” (Asti) – Italy

Speed and savings. Even distribution of heat in the tank

Clever heating of the bottom of the tank

The heating elements cover entirely the bottom of the tank which is divided into indipendent zones. Each one reaches and maintains the desired temperature, adjusting the power according to the needs.

Figaro is able to understand the amount of energy needed in each zone of the tank and therefore adapts the power to the type and quantity of product in complete autonomy and automatically.

For example the unit is able avoid creation of overheated zones where there is no product, thus facilitating the cleaning operations.

Faster cooking with pressure

A new way of managing pressure

Pressure lid – 0.45 bar, 110°C

Clever pressure management: Electronically controlled, self-regulating temperature in the different heating zones on the bottom of the tank: the working pressure is reached more efficiently;

Ad hoc pressure: The electronic board guarantees the perfect pressure in the tank, depending on the type and quantity of the cooking product;

Less water: The clever pressure management allows to cook using a minimum amount of water;

No more exhaust vapours in the kitchen: Safe and fast condensation of vapours, cooled with water;

Higher safety level: Sutomatic lid closure with side safety latch, software safety and safety valves;

Motorised systems: Tilting, lid and basket lifting system;

Altitude management: Self-regulating settings based on the altitude at which the machine is installed.